Likaroloana

- Bakeng sa li-shaft tse sa hatakeloang

- Tiiso e le 'ngoe

- E leka-lekaneng

- Ho sa tsotelehe hore na potoloho e tsamaea joang

- Melumo ea tšepe e potolohang

Melemo

- Bakeng sa maemo a mocheso o feteletseng

- Ha ho na O-Ring e kentsoeng ka matla

- Tšusumetso ea ho itlhoekisa

- Bolelele bo bokhutšoanyane ba ho kenya bo ka khoneha

- Sekurufu sa ho pompa bakeng sa mecha ea phatlalatso e nang le viscous e fumanehang (ho itšetlehile ka tsela eo e potolohang ka eona)

Sebaka sa Ts'ebetso

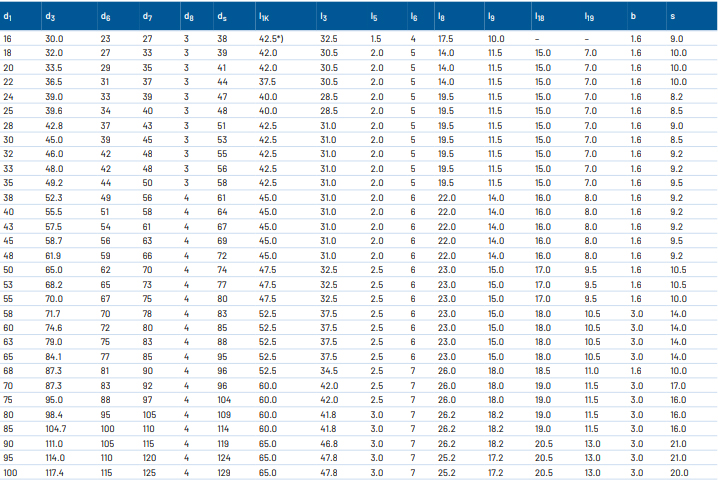

Bophara ba mokoti:

d1 = 16 … 100 mm (0.63" … 4")

Khatello e tsoang kantle:

p1 = … 25 bare (363 PSI)

Khatello ea ka hare:

p1 <120 °C (248 °F) 10 bar (145 PSI)

p1 <220 °C (428 °F) 5 bar (72 PSI)

Mocheso: t = -40 °C … +220 °C

(-40 °F … 428) °F,

Ho hlokahala senotlolo sa setulo se sa sisinyeheng.

Lebelo la ho thella: vg = 20 m/s (66 ft/s)

Lintlha: Mefuta e fapaneng ea preesure, mocheso le lebelo la ho thella e itšetlehile ka litiiso

Lisebelisoa tsa Motsoako

Sefahleho sa Rotary

Silicon carbide (RBSIC)

Resin ea carbon graphite e tšetsoeng

Carbide ea Tungsten

Setulo se sa sisinyeheng

Silicon carbide (RBSIC)

Carbide ea Tungsten

Elastomer

Rabara ea Fluorocarbon (Viton)

Ethylene-Propylene-Diene (EPDM)

Viton ea Enwrap ea PTFE

Li-bellow

Motsoako C-276

Tšepe e sa Hlakeng (SUS316)

Tšepe e sa Khaotseng ea AM350

Motsoako oa 20

Likarolo

Tšepe e sa Hlakeng (SUS304)

Tšepe e sa Hlakeng (SUS316)

Mediums:Metsi a chesang, oli, hydrocarbon e metsi, asiti, alkali, di-solvents, pampiri ya pampiri le dikahare tse ding tse nang le viscosity e mahareng le e tlase.

Likopo tse Khothaletsoang

- Indasteri ea ts'ebetso

- Indasteri ea oli le khase

- Theknoloji ea ntlafatso

- Indasteri ea Petrochemical

- Indasteri ea lik'hemik'hale

- Mecha ea litaba e chesang

- Mecha ea phatlalatso e batang

- Mecha ea phatlalatso e tiileng haholo

- Lipompo

- Lisebelisoa tse khethehileng tse potolohang

- Oli

- Hydrocarbon e bobebe

- Hydrocarbon e nkhang hamonate

- Li-solvent tsa tlhaho

- Li-acid tsa beke

- Ammonia

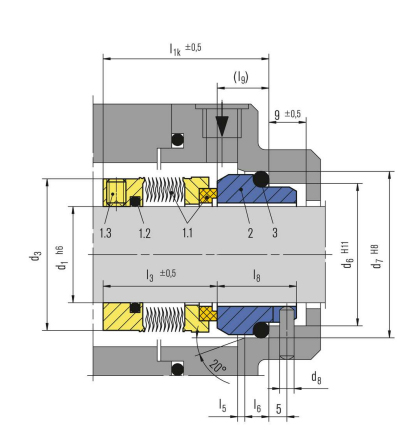

Nomoro ea Karolo ea Ntho DIN 24250 Tlhaloso

1.1 472/481 Sefahleho sa tiiso se nang le yuniti ea bellows

1.2 412.1 O-Ring

Sekurufu sa Sete sa 1.3 904

Litulo tse 2 475 (G9)

3 412.2 O-Ring

Leqephe la data la tekanyo ea WMFL85N (mm)