E khomarela molao-motheo oa hau oa "Botšepehi, mafolofolo, boqapi, boqapi" ho hlahisa litharollo tse ncha kamehla. E nka bareki, katleho e le katleho ea eona. A re ntlafatseng bokamoso bo atlehileng re tšoarane ka matsoho bakeng sa tiiso ea pompo ea metsi bakeng sa indasteri ea likepe, Re amohela metsoalle ka tieo ho buisana ka khoebo le ho qala tšebelisano-'moho. Re tšepa ho ikopanya le metsoalle indastering e fapaneng ho hlahisa bokamoso bo ikhethang bo ka bonoang esale pele.

E khomarela molao-motheo oa hau oa "Botšepehi, mafolofolo, boqapi, boqapi" ho hlahisa litharollo tse ncha kamehla. E nka bareki, katleho e le katleho ea eona. A re ntlafatseng bokamoso bo atlehileng re tšoarane ka matsoho bakeng sa, Ka mefuta e mengata, boleng bo botle, litheko tse utloahalang le meralo e metle, lihlahisoa tsa rona li sebelisoa haholo lefapheng lena le liindastering tse ling. Re amohela bareki ba bacha le ba khale ba tsoang maemong 'ohle a bophelo ho ikopanya le rona bakeng sa likamano tsa khoebo tsa nakong e tlang le ho fihlela katleho ea bobeli! Re amohela bareki, mekhatlo ea khoebo le metsoalle e tsoang likarolong tsohle tsa lefats'e ho ikopanya le rona le ho batla tšebelisano-'moho bakeng sa melemo ea bobeli.

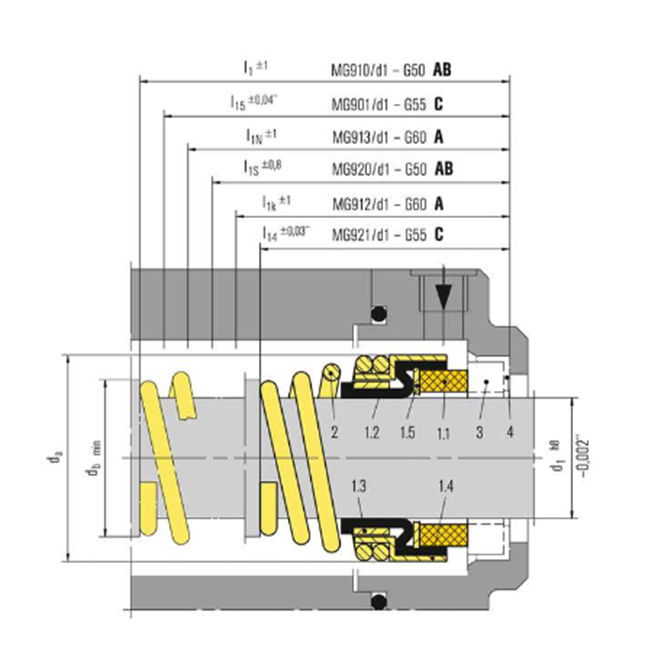

Likaroloana

•Bakeng sa li-shaft tse sa rarahanang

•Seliba se le seng

•Elastomer e benya e potoloha

•E leka-lekaneng

•Ha e itšetlehe ka tsela eo potoloho e leng ka eona

•Ha ho na ho torsion holim'a bellows le spring

•Seliba se kobehileng kapa se nang le selika-likoe

• Boholo ba metric le inch boa fumaneha

•Litekanyo tse khethehileng tsa litulo lia fumaneha

Melemo

•E lekana sebakeng sefe kapa sefe sa ho kenya ka lebaka la bophara bo bonyenyane ba tiiso ea kantle

•Litumello tsa bohlokoa tsa thepa lia fumaneha

• Bolelele ba ho kenya ka bomong bo ka fihlelleha

•Ho tenyetseha ho hoholo ka lebaka la khetho e telele ea thepa

Lisebelisoa tse khothaletsoang

•Theknoloji ea metsi le litšila

• Indasteri ea makhasi le pampiri

• Indasteri ea lik'hemik'hale

•Maro a phodisang

•Media e nang le dikahare tse tlase tsa dintho tse tiileng

Oli ea khatello bakeng sa mafura a biodiesel

•Lipompo tse potolohang

•Lipompo tse ka qoelisoang ka metsing

•Lipompo tsa mekhahlelo e mengata (lehlakoreng le sa kgannweng)

•Lipompo tsa metsi le tsa litšila

•Lisebelisoa tsa oli

Mefuta e sebetsang

Bophara ba mokoti:

d1 = 10 … 100 mm (0.375″ … 4″)

Khatello: p1 = 12 bare (174 PSI),

vacuum cleaner ho fihlela ho 0.5 bar (7.25 PSI),

ho fihlela ho 1 bar (14.5 PSI) e nang le setulo se notleloang

Mocheso:

t = -20 °C … +140 °C (-4 °F … +284 °F)

Lebelo la ho thella: vg = 10 m/s (33 ft/s)

Motsamao oa Axial: ± 0.5 mm

Lisebelisoa tsa motsoako

Lesale le sa sisinyeheng: Ceramic, Carbon, SIC, SSIC, TC

Lesale le potolohang: Ceramic, Carbon, SIC, SSIC, TC

Tiiso ea Bobeli: NBR/EPDM/Viton

Likarolo tsa Selemo le Tšepe: SS304/SS316

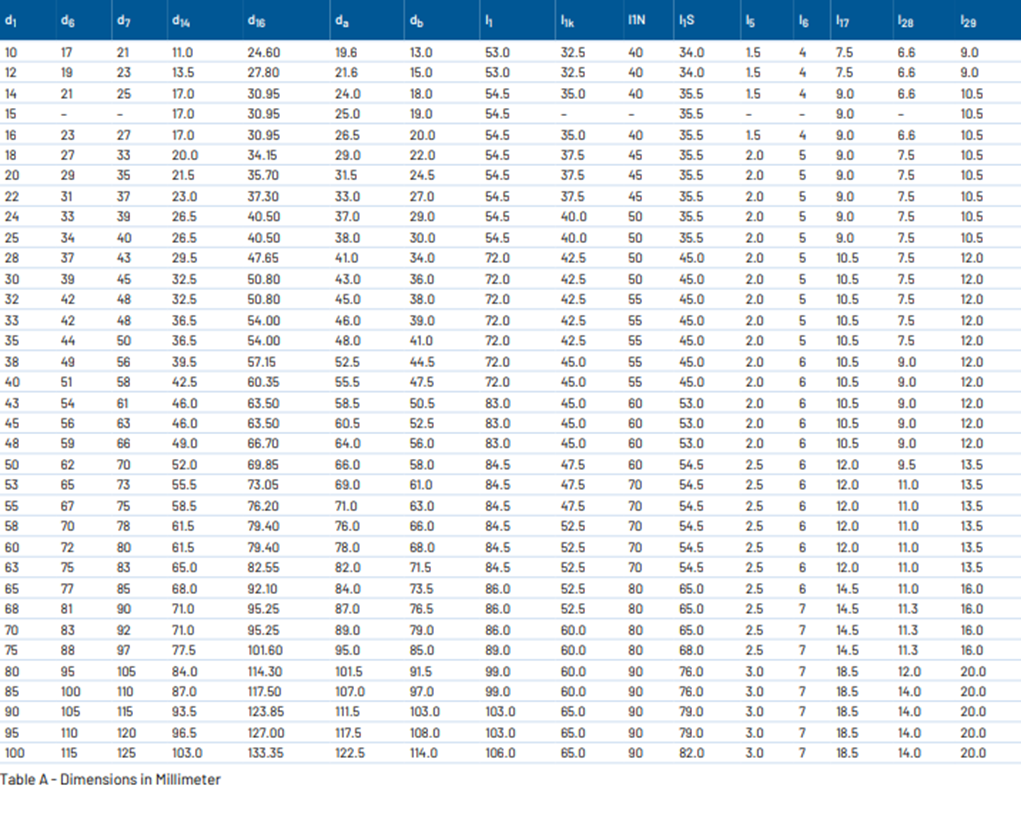

Leqephe la data la WMG912 la tekanyo(mm)

tiiso ea pompo ea mechini bakeng sa indasteri ea likepe

tiiso ea pompo ea mechini bakeng sa indasteri ea likepe