Ka theknoloji ea rona e etellang pele ka nako e le 'ngoe le moea oa rona oa boqapi, tšebelisano-'moho, melemo le kholo, re tla haha bokamoso bo atlehileng hammoho le feme ea hau e hlomphehang bakeng satiiso ea mechine ea rabara e benyangs MG1 bakeng sa indasteri ea likepe, Re u amohela hore u etele lefapha la rona la tlhahiso 'me u lebelle ho theha likamano tse amohelang tsa mokhatlo le bareki lapeng la hau le mose ho maoatle haufi le bokamoso bo bonahalang.

Ka theknoloji ea rona e etellang pele ka nako e le 'ngoe le moea oa rona oa boqapi, tšebelisano-'moho, melemo le kholo, re tla haha bokamoso bo atlehileng hammoho le feme ea hau e hlomphehang bakeng sapompo ea mechini sral, Tiiso ea Moqomo oa Pompo, tiiso ea mechine ea rabara e benyang, Tiiso ea Pompo ea Metsi, Re fana ka tšebeletso ea botsebi, karabo e potlakileng, ho fana ka thepa ka nako, boleng bo botle le theko e ntle ho bareki ba rona. Khotsofalo le mokitlane o motle ho moreki e mong le e mong ke tsa bohlokoa ho rona. Re tsepamisa maikutlo ntlheng e 'ngoe le e 'ngoe ea ts'ebetso ea odara bakeng sa bareki ho fihlela ba fumane lihlahisoa tse sireletsehileng le tse ntle tse nang le tšebeletso e ntle ea thepa le litšenyehelo tse tlase. Ho latela sena, lihlahisoa tsa rona li rekisoa hantle haholo linaheng tsa Afrika, Bohareng ba Bochabela le Asia Boroa-bochabela.

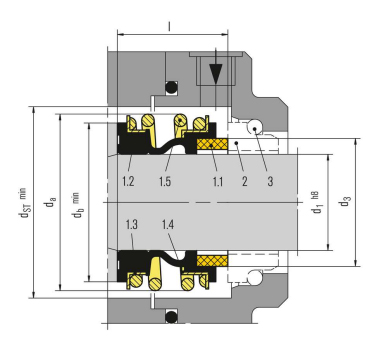

Phetolo ea litiiso tse ka tlase tsa mechini

AESSEAL B02, BURGMANN MG1, FLOWSERVE 190

Likaroloana

- Bakeng sa li-shaft tse sa rarahanang

- Tiiso e le 'ngoe le e habeli

- Elastomer e benya e potoloha

- E leka-lekaneng

- Ho sa tsotelehe hore na potoloho e tsamaea joang

- Ha ho na ho torsion holim'a bellows

Melemo

- Tšireletso ea shaft holim'a bolelele bohle ba tiiso

- Tšireletso ea sefahleho sa tiiso nakong ea ho kenngoa ka lebaka la moralo o khethehileng oa bellows

- Ha e na kutloelo-bohloko ho kheloha ha shaft ka lebaka la bokhoni bo boholo ba ho sisinyeha ha axial

- Menyetla ea kopo ea bokahohleng

- Lisetifikeiti tsa bohlokoa tsa thepa lia fumaneha

- Ho tenyetseha ho hoholo ka lebaka la tlhahiso e pharaletseng ea thepa

- E loketse lits'ebetso tse se nang likokoana-hloko tse tlase

- Moralo o khethehileng oa lipompo tsa metsi a chesang (RMG12) oa fumaneha

- Litokisetso tsa boholo le litulo tse ling lia fumaneha

Sebaka sa Ts'ebetso

Bophara ba mokoti:

d1 = 10 … 100 mm (0.39″ … 3.94″)

Khatello: p1 = 16 bare (230 PSI),

vacuum … 0.5 bare (7.25 PSI),

ho fihlela ho 1 bar (14.5 PSI) e nang le setulo se notleloang

Mocheso: t = -20 °C … +140 °C

(-4 °F … +284 °F)

Lebelo la ho thella: vg = 10 m/s (33 ft/s)

Motsamao o amohelehang oa axial: ± 2.0 mm (± 0,08″)

Lisebelisoa tsa Motsoako

Sefahleho sa Rotary

Resin ea carbon graphite e tšetsoeng

Khabone e hatellang ka mocheso

Silicon carbide (RBSIC)

Setulo se sa sisinyeheng

Aluminium oxide (Seramiki)

Silicon carbide (RBSIC)

Carbide ea Tungsten

Tiiso e Thusang

Nitrile-Butadiene-Rabber (NBR)

Rabara ea Fluorocarbon (Viton)

Ethylene-Propylene-Diene (EPDM)

Selemo

Tšepe e sa Hlakeng (SUS304)

Likarolo tsa Tšepe

Tšepe e sa Hlakeng (SUS304)

Likopo tse Khothaletsoang

- Phepelo ea metsi a hloekileng

- Boenjiniere ba lits'ebeletso tsa kaho

- Theknoloji ea metsi a litšila

- Theknoloji ea lijo

- Tlhahiso ea tsoekere

- Indasteri ea makhasi le pampiri

- Indasteri ea oli

- Indasteri ea Petrochemical

- Indasteri ea lik'hemik'hale

- Metsi, metsi a litšila, marotholi (lintho tse tiileng ho fihlela ho 5% ka boima)

- Makhasi (ho fihlela ho 4% ho feta)

- Latex

- Mabese, lino tse tahang

- Marotholi a sulfide

- Lik'hemik'hale

- Oli

- Lipompo tse tloaelehileng tsa lik'hemik'hale

- Lipompo tsa sekere tsa Helical

- Lipompo tsa thepa

- Lipompo tse potolohang

- Lipompo tse ka qoelisoang ka metsing

- Lipompo tsa metsi le metsi a litšila

- Lisebelisoa tsa oli

Lintlha

WMG1 e ka boela ea sebelisoa e le tiiso e mengata e kopantsoeng ka nako e le 'ngoe kapa ka tokisetso ea ho latellana. Litlhahiso tsa ho kenya lia fumaneha ha ho kopuoa.

Litokiso tsa boholo bakeng sa maemo a itseng, mohlala, shaft ka lisenthimithara kapa litekanyo tse khethehileng tsa setulo lia fumaneha ha ho kopuoa.

Nomoro ea Karolo ea Ntho ho ea ho DIN 24250 Tlhaloso

1.1 472 Sefahleho sa tiiso

1.2 481 Bellows

1.3 484.2 Lesale la L (kholara ea selemo)

1.4 484.1 Lesale la L (kholara ea selemo)

1.5 477 Selemo

Litulo tse 2 475

3 412 O-Ring kapa rabara ea kopi

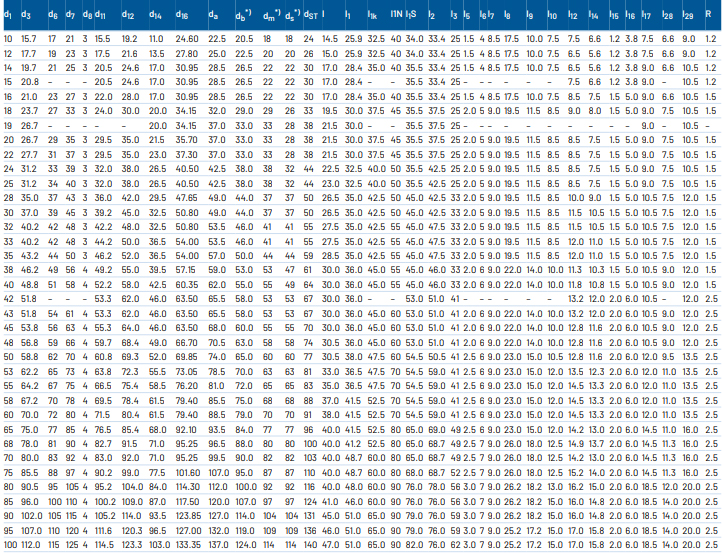

Leqephe la letsatsi la tekanyo ea WMG1 (mm)

litiiso tsa mechini bakeng sa indasteri ea likepe