Ha e le ka litheko tse hlōlisanang tsa thekiso, re lumela hore u tla be u batla ntho leha e le efe e ka re hlolang. Re tla bolela ka kholiseho e felletseng hore bakeng sa boleng bo holimo joalo ka litefiso tse joalo re tlaase ka ho fetisisa bakeng sa tiiso ea rabara ea mochini bakeng sa indasteri ea likepe ea MG1, 'Me ho na le metsoalle e mengata ea machabeng e tlileng ho bona libaka tse ntle, kapa e re fileng hore re ba rekele lintho tse ling. U ka 'na ua amoheleha haholo ho fihla Chaena, motseng oa rona le fekthering ea rona!

Ha e le ka litheko tsa thekiso tse hlōlisanang, re lumela hore u tla be u batla hole le hole ntho efe kapa efe e ka re hlolang. Re tla bolela ka tieo hore bakeng sa tse ntle joalo ka litefiso tse joalo re tlase ka ho fetisisa bakeng sa, Kaha kamehla, re khomarela litekanyetso tsa "ho buleha le ho lekana, ho arolelana ho fumana, ho phehella bokhabane, le ho theha boleng", re khomarela filosofi ea khoebo ea "botšepehi le bo sebetsang, bo shebaneng le khoebo, tsela e molemohali, valve e ntle ka ho fetisisa". Hammoho le lefats'e ka bophara re na le makala le balekane ho nts'etsapele libaka tse ncha tsa khoebo, litekanyetso tse tloaelehileng tse phahameng. Re amohela ka tieo 'me hammoho re arolelana mehloli ea lefats'e, re bula mosebetsi o mocha hammoho le khaolo.

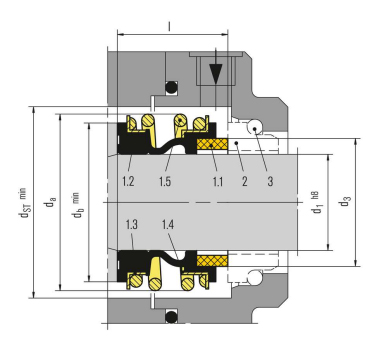

Phetolo ea litiiso tse ka tlase tsa mechini

AESSEAL B02, BURGMANN MG1, FLOWSERVE 190

Likaroloana

- Bakeng sa li-shaft tse sa rarahanang

- Tiiso e le 'ngoe le e habeli

- Elastomer e benya e potoloha

- E leka-lekaneng

- Ho sa tsotelehe hore na potoloho e tsamaea joang

- Ha ho na ho torsion holim'a bellows

Melemo

- Tšireletso ea shaft holim'a bolelele bohle ba tiiso

- Tšireletso ea sefahleho sa tiiso nakong ea ho kenngoa ka lebaka la moralo o khethehileng oa bellows

- Ha e na kutloelo-bohloko ho kheloha ha shaft ka lebaka la bokhoni bo boholo ba ho sisinyeha ha axial

- Menyetla ea kopo ea bokahohleng

- Lisetifikeiti tsa bohlokoa tsa thepa lia fumaneha

- Ho tenyetseha ho hoholo ka lebaka la tlhahiso e pharaletseng ea thepa

- E loketse lits'ebetso tse se nang likokoana-hloko tse tlase

- Moralo o khethehileng oa lipompo tsa metsi a chesang (RMG12) oa fumaneha

- Litokisetso tsa boholo le litulo tse ling lia fumaneha

Sebaka sa Ts'ebetso

Bophara ba mokoti:

d1 = 10 … 100 mm (0.39″ … 3.94″)

Khatello: p1 = 16 bare (230 PSI),

vacuum … 0.5 bare (7.25 PSI),

ho fihlela ho 1 bar (14.5 PSI) e nang le setulo se notleloang

Mocheso: t = -20 °C … +140 °C

(-4 °F … +284 °F)

Lebelo la ho thella: vg = 10 m/s (33 ft/s)

Motsamao o amohelehang oa axial: ± 2.0 mm (± 0,08″)

Lisebelisoa tsa Motsoako

Sefahleho sa Rotary

Resin ea carbon graphite e tšetsoeng

Khabone e hatellang ka mocheso

Silicon carbide (RBSIC)

Setulo se sa sisinyeheng

Aluminium oxide (Seramiki)

Silicon carbide (RBSIC)

Carbide ea Tungsten

Tiiso e Thusang

Nitrile-Butadiene-Rabber (NBR)

Rabara ea Fluorocarbon (Viton)

Ethylene-Propylene-Diene (EPDM)

Selemo

Tšepe e sa Hlakeng (SUS304)

Likarolo tsa Tšepe

Tšepe e sa Hlakeng (SUS304)

Likopo tse Khothaletsoang

- Phepelo ea metsi a hloekileng

- Boenjiniere ba lits'ebeletso tsa kaho

- Theknoloji ea metsi a litšila

- Theknoloji ea lijo

- Tlhahiso ea tsoekere

- Indasteri ea makhasi le pampiri

- Indasteri ea oli

- Indasteri ea Petrochemical

- Indasteri ea lik'hemik'hale

- Metsi, metsi a litšila, marotholi (lintho tse tiileng ho fihlela ho 5% ka boima)

- Makhasi (ho fihlela ho 4% ho feta)

- Latex

- Mabese, lino tse tahang

- Marotholi a sulfide

- Lik'hemik'hale

- Oli

- Lipompo tse tloaelehileng tsa lik'hemik'hale

- Lipompo tsa sekere tsa Helical

- Lipompo tsa thepa

- Lipompo tse potolohang

- Lipompo tse ka qoelisoang ka metsing

- Lipompo tsa metsi le metsi a litšila

- Lisebelisoa tsa oli

Lintlha

WMG1 e ka boela ea sebelisoa e le tiiso e mengata e kopantsoeng ka nako e le 'ngoe kapa ka tokisetso ea ho latellana. Litlhahiso tsa ho kenya lia fumaneha ha ho kopuoa.

Litokisetso tsa boholo bakeng sa maemo a itseng, mohlala, shaft ka lisenthimithara kapa litekanyo tse khethehileng tsa setulo lia fumaneha ha ho kopuoa.

Nomoro ea Karolo ea Ntho ho ea ho DIN 24250 Tlhaloso

1.1 472 Sefahleho sa tiiso

1.2 481 Bellows

1.3 484.2 Lesale la L (kholara ea selemo)

1.4 484.1 Lesale la L (kholara ea selemo)

1.5 477 Selemo

Litulo tse 2 475

3 412 O-Ring kapa rabara ea kopi

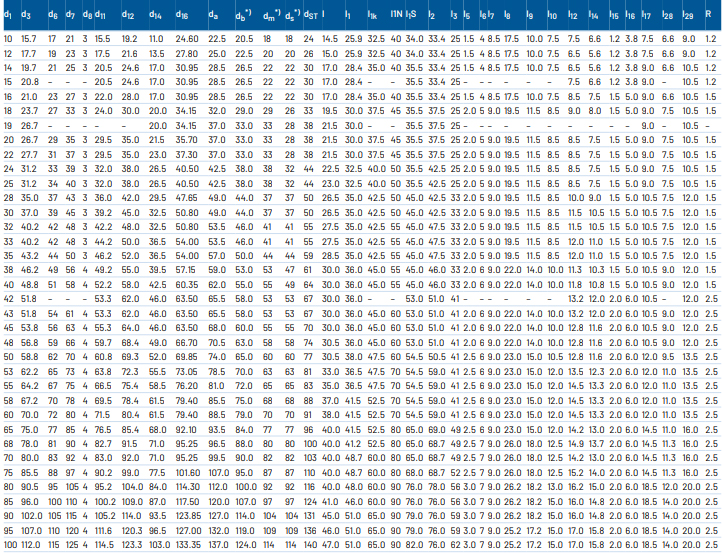

Leqephe la letsatsi la tekanyo ea WMG1 (mm)

Tiiso ea mechini ea rabara ea MG1 e ka hare bakeng sa indasteri ea likepe