Hangata re nahana le ho itloaetsa ho latela phetoho ea maemo a hau, 'me rea hola. Re ikemiselitse ho fihlela kelello le 'mele o ruileng hammoho le bophelo bakeng sa rabara e ka tlase ho tiiso ea mechini eMG1 bakeng sa indasteri ea likepe, Re ikemiselitse ho ntlafatsa sistimi e tsoelang pele, boqapi ba tsamaiso, boqapi ba maemo a holimo le boqapi ba indasteri, re fana ka tšebeliso e felletseng melemong eohle, 'me re tsoela pele ho ntlafatsa litšebeletso tsa boleng bo holimo.

Hangata re nahana le ho itloaetsa ho latela phetoho ea maemo a hau, 'me rea hola. Re ikemiseditse ho fihlela kelello le 'mele o ruileng hammoho le bophelo ba rona, Jwalo ka fektheri e nang le boiphihlelo re boetse re amohela odara e ikhethileng mme re e etsa e tšoanang le setšoantšo sa hau kapa sampole e hlalosang litlhaloso le sephutheloana sa moralo oa bareki. Sepheo se seholo sa k'hamphani ke ho phela mohopolo o khotsofatsang ho bareki bohle, le ho theha kamano ea khoebo ea nako e telele ea bohle. Bakeng sa tlhaiso-leseling e batsi, etsa bonnete ba hore o ikopanya le rona. 'Me ke thabo ea rona e kholo haeba u rata ho ba le seboka sa botho ofising ea rona.

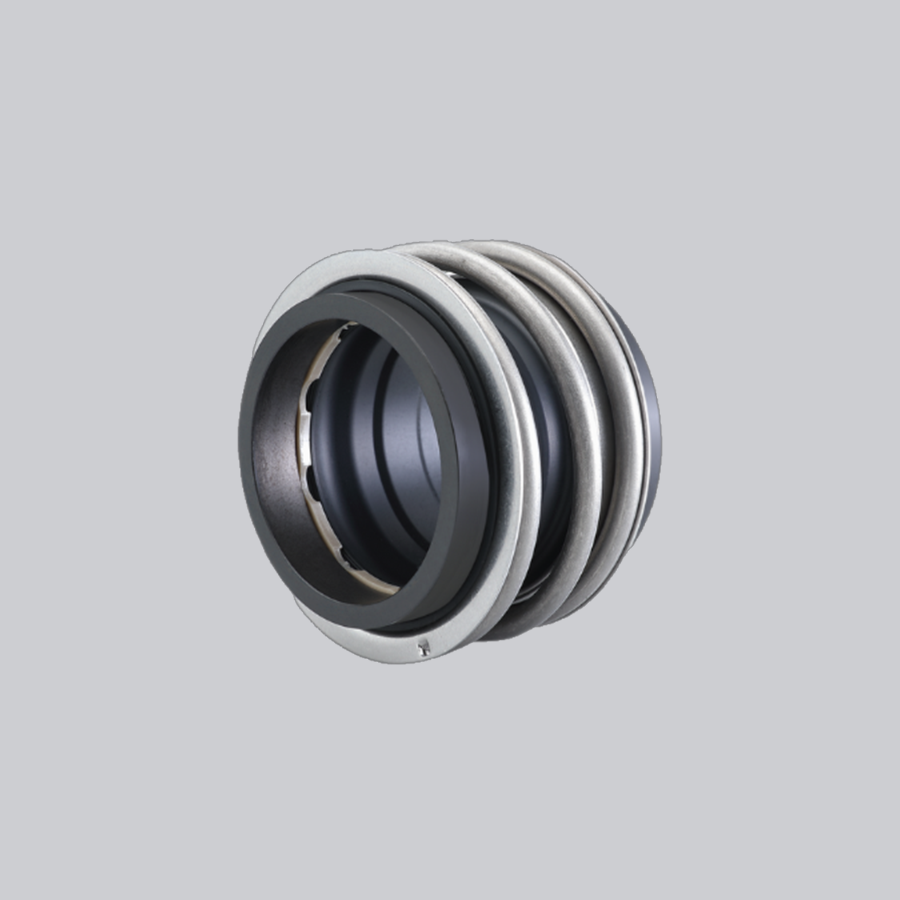

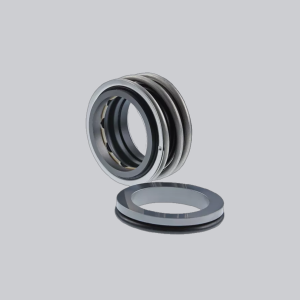

Likaroloana

Bakeng sa li-shaft tse sa rarahanang

Tiiso e le 'ngoe le e habeli

Elastomer e benya e potoloha

E leka-lekaneng

Ho sa tsotelehe hore na teko ea ho potoloha e shebane le tataiso efe

Melemo

- E lumellana ka 100% leMG1

- Bophara bo bonyenyane ba kantle ba tšehetso ea bellows (dbmin) bo nolofalletsa tšehetso ea lesale le tšoarellang ka kotloloho, kapa mehele e menyenyane ea sebaka

- Tšobotsi e ntle ea ho hokahanya ka ho itlhoekisa disk/shaft

- Ho ntlafatsa ho tsepamisa maikutlo ho pholletsa le mefuta eohle ea ts'ebetso ea khatello

- Ha ho na ho torsion holim'a bellows

- Tšireletso ea shaft holim'a bolelele bohle ba tiiso

- Tšireletso ea sefahleho sa tiiso nakong ea ho kenngoa ka lebaka la moralo o khethehileng oa bellows

- Ha e na kutloelo-bohloko ho kheloha ha shaft ka lebaka la bokhoni bo boholo ba ho sisinyeha ha axial

- E loketse lits'ebetso tse se nang likokoana-hloko tse tlase

Lisebelisoa tse khothaletsoang

- Phepelo ea metsi a hloekileng

- Boenjiniere ba lits'ebeletso tsa kaho

- Theknoloji ea metsi a litšila

- Theknoloji ea lijo

- Tlhahiso ea tsoekere

- Indasteri ea makhasi le pampiri

- Indasteri ea oli

- Indasteri ea Petrochemical

- Indasteri ea lik'hemik'hale

- Metsi, metsi a litšila, marotholi a metsi

(lintho tse tiileng ho fihlela ho 5% ka boima) - Makhasi (ho fihlela ho 4% ho feta)

- Latex

- Mabese, lino tse tahang

- Marotholi a sulfide

- Lik'hemik'hale

- Oli

- Lipompo tse tloaelehileng tsa lik'hemik'hale

- Lipompo tsa sekere tsa Helical

- Lipompo tsa thepa

- Lipompo tse potolohang

- Lipompo tse ka qoelisoang ka metsing

- Lipompo tsa metsi le metsi a litšila

s

Mefuta e sebetsang

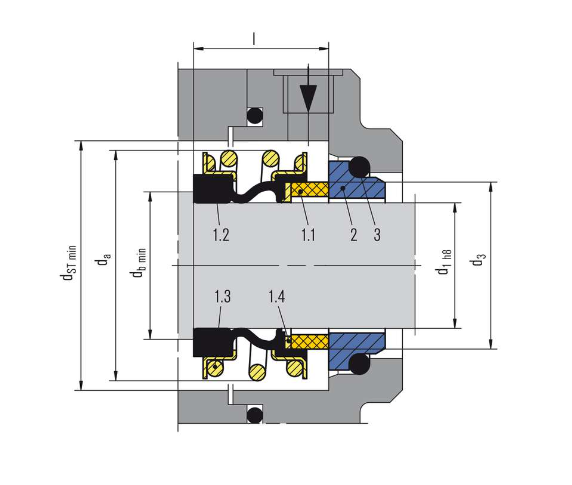

Bophara ba mokoti:

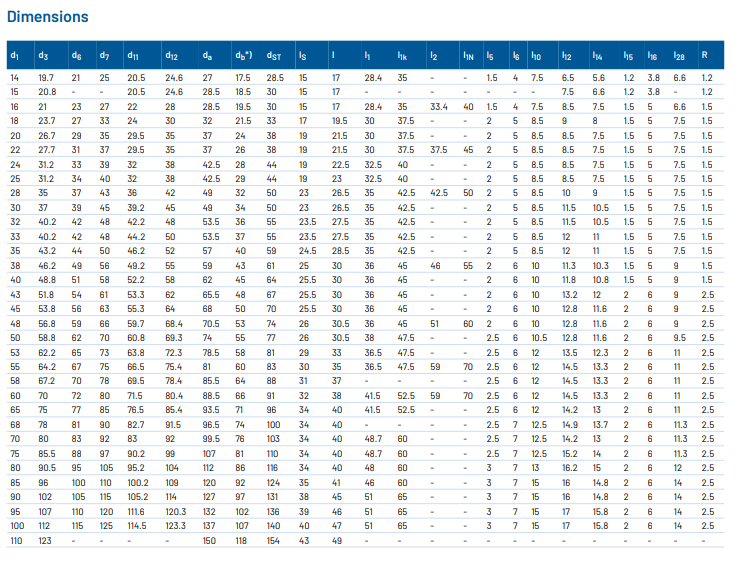

d1 = 14 … 110 mm (0.55″ … 4.33″)

Khatello: p1 = 18 bare (261 PSI),

vacuum … 0.5 bare (7.25 PSI),

ho fihlela ho 1 bar (14.5 PSI) e nang le setulo se notleloang

Mocheso: t = -20 °C … +140 °C

(-4 °F … +284 °F)

Lebelo la ho thella: vg = 10 m/s (33 ft/s)

Motsamao o amohelehang oa axial: ± 2.0 mm (± 0.08″)

Lisebelisoa tsa motsoako

Lesale le sa sisinyeheng: Ceramic, Carbon, SIC, SSIC, TC

Lesale le potolohang: Ceramic, Carbon, SIC, SSIC, TC

Tiiso ea Bobeli: NBR/EPDM/Viton

Likarolo tsa Selemo le Tšepe: SS304/SS316

Leqephe la data la WeMG1 la tekanyo(mm)

tiiso ea pompo ea mechini bakeng sa indasteri ea likepe