Re tsitlallela ho fana ka tlhahiso ea boleng bo holimo ka mohopolo o motle oa khoebo, thekiso ea lihlahisoa tse tšepahalang le tšebeletso e ntle ka ho fetisisa le e potlakileng. E ke ke ea u tlisetsa tharollo ea boleng bo holimo feela le phaello e kholo, empa ea bohlokoa ka ho fetisisa e lokela ho ba ho lula 'marakeng o sa feleng oa tiiso ea mechini ea O ring bakeng sa pompo ea leoatle H7N, Re amohela bareki ka botlalo ho tsoa lefats'eng lohle ho theha mekhatlo e meholo ea likhoebo tse nyane e tsitsitseng le e thusang ka bobeli, ho ba le bokamoso bo khanyang hammoho.

Re tsitlallela ho fana ka tlhahiso ea boleng bo holimo e nang le mohopolo o motle oa khoebo, thekiso ea lihlahisoa tse tšepahalang le tšebeletso e ntle ka ho fetisisa le e potlakileng. E ke ke ea u tlisetsa tharollo ea boleng bo holimo feela le phaello e kholo, empa ea bohlokoa ka ho fetisisa e lokela ho ba ho lula 'marakeng o sa feleng bakeng saTiiso ea mechini ea H7N, Tiiso ea Mechanical ea O Ring, Tiiso ea Moqomo oa Pompo ea Metsi, Ka lihlahisoa tse ngata tsa Chaena lefatšeng ka bophara, khoebo ea rona ea machabeng e ntse e hola ka potlako 'me matšoao a moruo a eketseha haholo selemo le selemo. Re na le kholiseho e lekaneng ea ho u fa lihlahisoa le tšebeletso e betere, hobane re matla le ho feta, re litsebi ebile re na le boiphihlelo malapeng le machabeng.

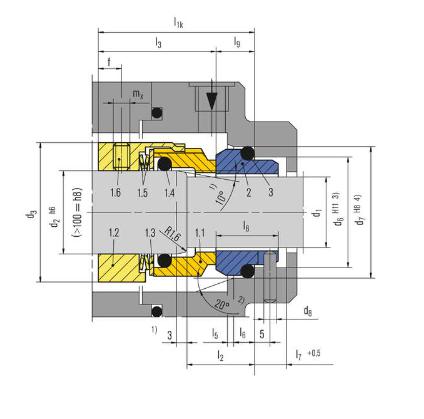

Likaroloana

•Bakeng sa li-shaft tse nang le litepisi

• Setiiso se le seng

•E leka-lekaneng

•Super-Sinus-spring kapa li-spring tse ngata tse potolohang

•Ha e itšetlehe ka tsela eo potoloho e leng ka eona

•Sesebelisoa se kopaneng sa ho pompa sea fumaneha

•Mofuta o mong o nang le ho pholisa setulo o fumaneha

Melemo

•Menyetla ea kopo ea bokahohleng (ho etsa maemo a tloaelehileng)

• Ho boloka thepa ka katleho ka lebaka la lifahleho tse ka fapanyetsanoang habonolo

• Khetho e atolositsoeng ea thepa

•Ho tenyetseha ha phetiso ea torque

•Tšusumetso ea ho itlhoekisa

•Bolelele bo bokhutšoanyane ba ho kenya bo ka khoneha (G16)

Lisebelisoa tse khothaletsoang

• Indasteri ea ts'ebetso

• Indasteri ea oli le khase

•Theknoloji ea ntlafatso

• Indasteri ea peterole

• Indasteri ea lik'hemik'hale

•Theknoloji ea feme ea motlakase

• Indasteri ea makhasi le pampiri

• Indasteri ea lijo le lino

•Lisebelisoa tsa metsi a chesang

•Li-hydrocarbon tse bobebe

•Lipompo tsa phepelo ea boiler

•Lipompo tsa ts'ebetso

Mefuta e sebetsang

Bophara ba mokoti:

d1 = 14 … 100 mm (0.55″ … 3.94″)

(Seliba se le seng: d1 = boholo ba 100 mm (3.94″))

Khatello:

p1 = 80 bare (1,160 PSI) bakeng sa d1 = 14 … 100 mm,

p1 = 25 bare (363 PSI) bakeng sa d1 = 100 … 200 mm,

p1 = 16 bare (232 PSI) bakeng sa d1 > 200 mm

Mocheso:

t = -50 °C … 220 °C (-58 °F … 428 °F)

Lebelo la ho thella: vg = 20 m/s (66 ft/s)

Motsamao oa Axial:

d1 ho fihlela ho 22 mm: ± 1.0 mm

d1 24 ho fihlela ho 58 mm: ± 1.5 mm

d1 ho tloha ho 60 mm: ± 2.0 mm

Lisebelisoa tsa Motsoako

Sefahleho sa Rotary

Silicon carbide (RBSIC)

Resin ea carbon graphite e tšetsoeng

Carbide ea Tungsten

Tšepe ea Cr-Ni-Mo (SUS316)

Setulo se sa sisinyeheng

Silicon carbide (RBSIC)

Resin ea carbon graphite e tšetsoeng

Carbide ea Tungsten

Tiiso e Thusang

Rabara ea Fluorocarbon (Viton)

Ethylene-Propylene-Diene (EPDM)

Silicone-Rabara (MVQ)

VITON e koahetsoeng ka PTFE

Selemo

Tšepe e sa Hlakeng (SUS304)

Tšepe e sa Hlakeng (SUS316)

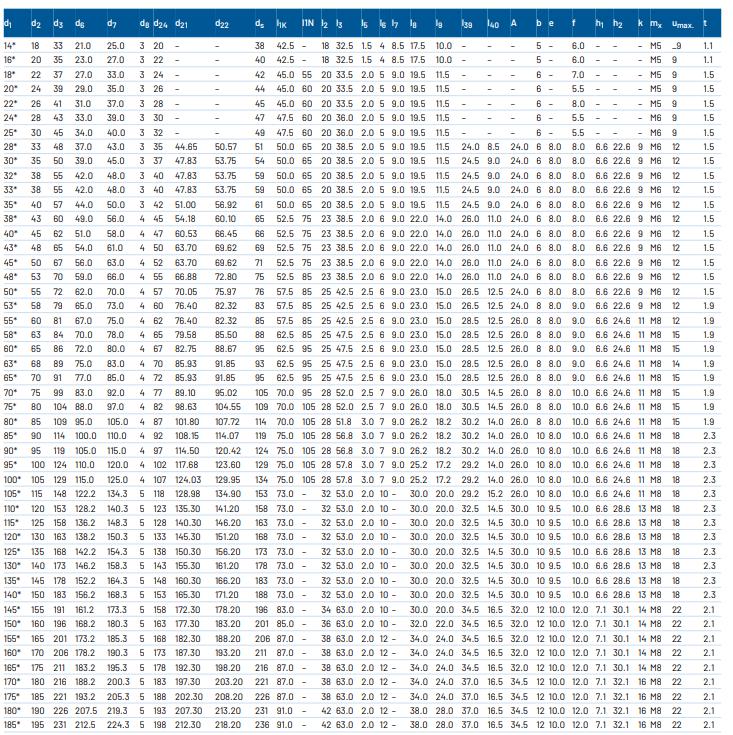

Leqephe la data la WH7N la boholo (mm)

LITŠIBI TSA MAQHUBU KE LITIISO TSE KGOLO TSE KOPANYETSENG TSE HLAHANG TSE ENTSWENG PELE LI ENTSWETSOE BAKENG SA BOLELE BO BOKHUTŠOANE BA TŠEBELETSO LE LITLHOKO TSA BOHLOEKI.

Li-spring tsa maqhubu ke litiiso tsa mechini tse etselitsoeng ho nkela li-spring tsa khatello ea terata e chitja tse tloaelehileng sebaka lits'ebetsong tse hlokang tlhaloso ea ho fapoha ha mojaro o thata tikolohong ea bohlokoa ea sebaka. Li fana ka mojaro o lekanang haholoanyane ho feta Parallel kapa Taper Spring, le tlhoko e nyane ea enfelopo ho fihlela mojaro o tšoanang oa sefahleho.

Litiiso tsa mechini tse shebaneng le mahlakore a mabeli li fana ka moralo o netefalitsoeng oa litiiso le theknoloji ea selemo sa maqhubu, ka mefuta e fapaneng ea metsoako ea thepa. Sena se ntlafatsoa ke likarolo tse ntle tsa moralo, tsohle ka litheko tse hlōlisanang haholo.

Tiiso ea mechini ea H7Nbakeng sa pompo ea metsing