U bapala karolo ea bohlokoa ho matlafatsa ts'ebetso ea pompo ha u khetha se nepahetsengpompo ea rotor sete. Ka ho khetha ka bohlale, u ka finyella ho fihlela3.87% ts'ebetso e phahameng'me u natefeloe ke nako e telele ea tlhokomelo. Liphuputso tsa morao-rao li bontša hore li-rotor tse ntlafalitsoeng li ka ba tsa eketsa phallo ea pompo ka 25%, e susumetsang tsoelo-pele ea sebele.

Lintlha tsa bohlokoa

- Ho khetha mofuta o nepahetseng oa pompo ea rotor le moralo ho matlafatsa ts'ebetso, phallo le nako ea bophelo ea pompo lits'ebetsong tse fapaneng.

- Ho khetha lisebelisoa tse nepahetseng le liphahlo tse tsoetseng pele ho ntlafatsa ho tšoarella ha rotor, ho fokotsa tlhokomelo, le ho boloka litšenyehelo.

- Tlhahlobo ea khafetsa le khetho e bohlale ea rotor e thusa ho qoba ho senyeha, ho fokotsa tšebeliso ea matla, le ho eketsa ts'ebetso ea pompo.

Li-Rotor tsa Pompo li sebetsa joang ka mefuta e fapaneng ea lipompo

Liroboto tsa Pompo ea Centrifugal

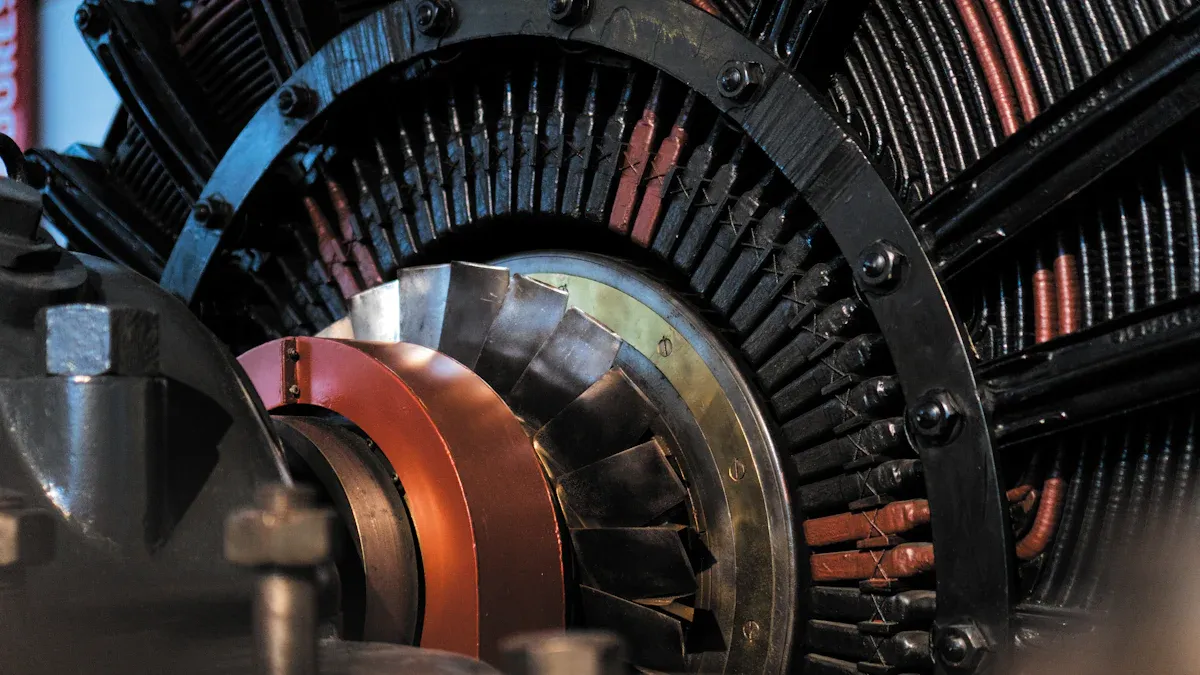

O ka notlolla matla a 'nete a motsamao oa mokelikeli ka centrifugalli-rotor tsa pompo. Li-rotor tsena, tse atisang ho bitsoa li-impellers, li bilika ka potlako ho etsa matla a matla a sutumelletsang metsi ka ntle ho tloha bohareng. Ketso ena e fetola matla a mochini ho tsoa ho enjene ho ea matla a kinetic, metsi a tsamaisang kapa maro a mang ka pompo le ho kena ho sistimi ea hau.

Ha u khetha pompo ea centrifugal, u ikopanya le liindasteri tse ngata lefatšeng ka bophara. Ha e le hantle, lipompo tsa centrifugal li ne li tšoere matla a maholo65% kabeloea 'maraka oa lipompo tsa indasteri ka 2021. U li bona hohle-ho tloha litsing tsa ho hloekisa metsi ho ea lifekthering tsa lik'hemik'hale-hobane li sebetsana le mefuta e mengata ea metsi le litekanyetso tsa phallo.

Keletso:Ho khetha moralo o nepahetseng oa impeller ho ka eketsa ts'ebetso le ts'epahalo ea pompo ea hau.

Ts'ebetso e fapana ho latela mokelikeli le geometry ea pompo. Ka mohlala, liteko li bontša hore lipompo tse ling tsa centrifugal li finyella a3.3% hlooho e phahamengka tharollo e itseng ha e bapisoa le metsi. Leha ho le joalo, ho fokotsa lebelo la rotor ho lebisa ho theoha ho hlokomelehang ha ts'ebetso. Lipapiso tsa lipalo li tiisa liphuputso tsena, li bonts'a hore lipompo tsa axial-flow li ka fihlela katleho e phahameng joalo ka86.3%, ha meralo e meng e ka oela ka tlase ho 80%. Liphapano tsena ke tsa bohlokoa ha u batla ho eketsa tlhahiso le ho fokotsa tšebeliso ea matla.

Mona ke ho sheba ka potlako lintlha tse tloaelehileng tsa pompo ea centrifugal:

| Tlhaloso / Parameter | Tlhaloso / Boleng |

|---|---|

| Mokhoa oa ho mamella ho leka-lekana | U = 4W/N (U in oz-in, W = e jereng koranta ea boima bo sa sisinyeheng, N = lebelo le phahameng la ts'ebeletso) |

| Sehlopha sa ISO | Hoo e ka bang 0.7 (ISO 1940-1) |

| Tlhokahalo ea ho leka-lekanya ea API 610 | Ho leka-lekanya ho matla ho ISO 1940-1 Kereiti ea 2.5 kapa ho feta |

| Bohlokoa ba ho leka-lekanya | E fokotsa ho thothomela, e eketsa bophelo ba ho beleha, 'me e fokotsa nako ea ho theoha |

U ka bona hore ho leka-lekanya ho nepahetseng le khetho ea moralo ho u thusa ho finyella ts'ebetso e bonolo le bophelo bo bolelele ba tšebeletso. Ha u kenya chelete ho rotor ea pompo ea centrifugal e nepahetseng, u ipehela katleho ho kopo leha e le efe.

Positive Displacement Pump Rotors

U ka itšetleha ka li-rotor tse ntle tsa pompo ha u hloka phallo e tsitsitseng, e tšepahalang - leha e le ka maro a teteaneng kapa a thellang. Li-rotor tsena li tšoasa palo e tsitsitseng ea mokelikeli ebe li e tsamaisa ka pompo ka ho potoloha ka 'ngoe. Moralo ona o u fa taolo e nepahetseng ea phallo, e etsa hore lipompo tsena li lokele liindasteri tse kang lijo, meriana, oli le khase.

U na le meralo e mengata ea rotor eo u ka khethang ho eona, e 'ngoe le e' ngoe e na le matla a ikhethang:

| Mofuta oa Pompo | Litšobotsi tsa Moralo oa Rotor | Melemo ea Katleho e Thehiloeng ho Moralo le ho Lokeha ha Kopo |

|---|---|---|

| Piston ea Circumferential | Li-rotor ha li ame kapa li mesh; tiiso e entsoeng pakeng tsa stators le rotor | Tšebetso e phahameng ka ho fetisisa ka viscosity e tlaase; theko e phahameng haholo |

| Lobe | Li-rotor tse haufi-ufi; litlhophiso tse ngata tsa lobe | E kholo bakeng sa lihlahisoa tse teteaneng; e sa sebetseng hantle ka viscosity e tlase |

| Twin-Screw | Li-spindle tse peli li tlosa sehlahisoa ka axially; pulsation e tlase | Ho sebetsana ka bonolo, ho apara ka tlaase, litšenyehelo tse phahameng |

Liteko tsa laboratori li bonts'a hore lipompo tsa piston tsa circumferential li benya ka maro a nang le viscosity e tlase, ha liqapi tsa lobe le li-twin-screw li ipabola ka thepa e teteaneng. U ka bona lipompo tsena li sebetsa liindastering tse ngata, ho tloha ho tsamaisa chokolete fekthering ea lipompong ho isa ho ho tsamaisa oli e tala sebakeng sa tlhoekiso.

Lithuto tsa liteko mabapi le lipompo tsa piston tse khannoang ke moea li senola hore ho eketsa li-accumulators tsa khatello ho ka fokotsa sekhahla sa khatello ho fihlela ho68%. Sena se bolela ts'ebetso e bonolo le ho fokotseha ho fokolang ha thepa ea hau. Ha u khetha rotor e nepahetseng ea phalliso, u fumana taolo, katleho le khotso ea kelello.

Progressive Cavity Pump Rotors

U ka fumana liphetho tse makatsang ka li-rotor tse ntseng li tsoela pele, haholo ha u tobane le maro a phephetsang kapa u hloka phallo e bonolo, e tsitsitseng. Li-rotor tsena li na le sebōpeho se ikhethang sa helical se tsamaisang mokelikeli ka letoto la likoti tse nyenyane tse tiisitsoeng. Moqapi ona o sebetsana le ntho e 'ngoe le e' ngoe ho tloha ho metsi a litšila ho ea ho li-slurries tse teteaneng habonolo.

Hlokomela:Lipompompo tse tsoelang pele ke tharollo ea hau bakeng sa lits'ebetso moo lipompo tse ling li sokolang.

Mekhoa e mecha ea morao-rao e entse hore li-rotor tsena li khahle le ho feta. Mohlala, moralo oa Vogelsang HiCone o o lumella ho lokisa boemo ba rotor, ho khutlisetsa khatello ea mantlha le ho lelefatsa nako ea bophelo ea rotor le stator ho fihlela ho.makhetlo a mane. U ka etsa liphetoho tsena ka letsoho kapa ka boiketsetso, ho boloka pompo ea hau e sebetsa joalo ka e ncha le ho fokotsa nako ea ho theoha.

Mona ke kamoo li-rotor tse tsoetseng pele tse tsoelang pele li ntlafatsa ts'ebetso:

| Numerical Data Aspect | Tlhaloso / Sephetho |

|---|---|

| Khatello ea Outlet | Liqapi tse ncha lia atlehakhatello e phahameng ea phalloho feta mehlala e tloaelehileng. |

| Axial Leakage Speed | Meralo e ntlafalitsoeng e bonts'a ho lutla ho fokolang, ho matlafatsa ts'ebetso. |

| Ka hare Compress Process | Khatello e khethehileng e eketsa khatello ea ho tsoa le ho matlafatsa motsamao oa mokelikeli. |

U rua molemo ka tšebeliso e tlase ea motlakase, linako tse telele tsa litšebeletso, le litšenyehelo tse fokotsehileng tsa tlhokomelo. Ka ho khetha rotor e tsoelang pele ea pompo ea cavity, o matlafatsa tsamaiso ea hau ho sebetsana le mesebetsi e thata ka kholiseho le katleho.

Pump Rotor Set: Lisebelisoa, Moralo, le Khetho

Lisebelisoa tse tloaelehileng tsa Rotor

O ka notlolla maemo a macha a ts'ebetso ka ho khetha lisebelisoa tse nepahetseng bakeng sa sete ea hau ea rotor ea pompo. Thepa e 'ngoe le e' ngoe e tlisa matla a ikhethang, 'me khetho ea hau e bopa ho tšoarella ha pompo, ho sebetsa hantle le litšenyehelo. Bakeng sa metsi a hloekileng, hangata o bonarotor tse entsoeng ka tšepe e entsoeng ka tšepe, aluminium, boronse, tšepe e sa hloekang, kapa polymer. Haeba u sebetsana le metsi a turbid, li-polymers e kanna ea se be khetho e ntle ka ho fetisisa. Ha u tsamaisa metsi ka lintho tse tiileng, aluminium ha e tšoanelehe. Bakeng sa metsi a chesang, tšepe, boronse le tšepe e sa hloekang. Metsing a leoatle, boronse kapa tšepe e sa hloekang lia hlahella, ha tšepe e entsoeng ka tšepe e haella. Lipompo tsa letamo le whirlpool li hloka li-impellers tsa polymer ho hanela litlamorao tse mpe tsa chlorine.

Lisebelisoa tse tsoetseng pele joalo kametsoako e nyalisitsoengba fetola papali. Hona joale o ka kopanya litšepe le li-polymers ho matlafatsa ho tšoarella le ho fokotsa khohlano. Liaparo tse sireletsang tse kang tungsten carbide, tse sebelisoang ke ho fafatsa mocheso kapa ho kenngoa ha mouoane oa lik'hemik'hale, li etsa hore rotor ea hau ea pompo e be thata khahlanong le ho khoptjoa le ho bola. Litlhahiso tsena li u thusa ho tsamaisa lipompo nako e telele, esita le libakeng tse thata.

Keletso:Khetho e nepahetseng ea thepa e ka lelefatsa bophelo ba pompo ea hau le ho fokotsa litšenyehelo tsa tlhokomelo.

Lithuto tsa lipalo-palo li bontšaE-glass fiber ke eona e bolokang chelete ka ho fetisisa ebile e sebelisoa haholoka metsoako ea rotor. Likhoele tsa k'habone li u fa matla a holimo le ho satalla, haholo-holo ha mokhathala e le ntho e tšoenyang, empa li bitsa chelete e ngata 'me li ka senya. Likhoele tsa Aramid li fana ka matla a maholo le ho hanyetsa tšusumetso, leha li fokola ka khatello. Li-composite tsa Hybrid li u lumella ho leka-lekanya litšenyehelo, matla le nako e telele. Lintlha tsa mokhathala li totobatsa tlhoko ea boleng bo phahameng ba tlhahiso le tlhahlobo ea nako e telele ho netefatsa hore mochini oa rotor oa pompo o lula o tšepahala.

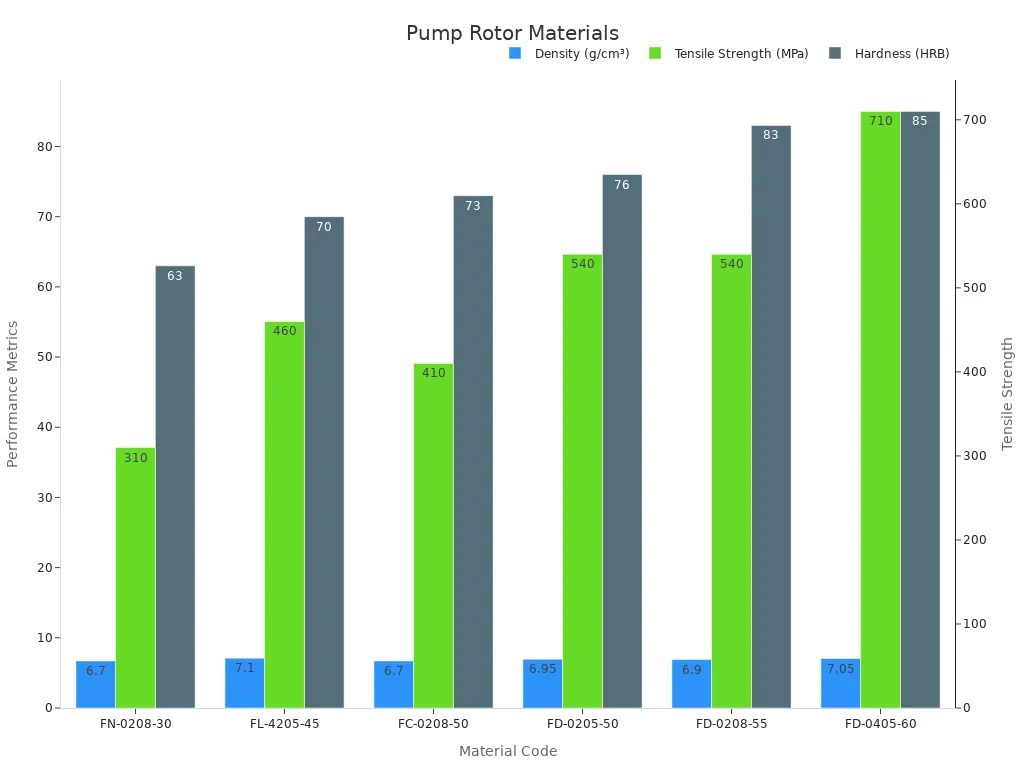

U ka bona phapang pakeng tsatshebetso ya lintho tse bonahalang tafoleng e ka tlaase:

| Khoutu ea lintho tse bonahalang | Boima ba 'mele (g/cm³) | Tensile Strength (MPa) | Ho thatafala (HRB) |

|---|---|---|---|

| FN-0208-30 | 6.70 | 310 | 63 |

| FL-4205-45 | 7.10 | 460 | 70 |

| FC-0208-50 | 6.70 | 410 | 73 |

| FD-0205-50 | 6.95 | 540 | 76 |

| FD-0208-55 | 6.90 | 540 | 83 |

| FD-0405-60 | 7.05 | 710 | 85 |

U ka boela ua bapisa thepa ena ka pono:

Liteko tsa morao-rao tsa ho tšoarella ho lirota tsa graphite li bontša seokhetho ea thepa e ama hore na sete ea rotor ea pompo ea hau e nka nako e kae. Ka mohlala, mofuta o mong oa rotor oa graphite o ile oa lahleheloa ke 36.9% feela ea thepa ea oona ka mor'a lipotoloho tse fetang 1,100 'me oa tsoela pele ho sebetsa, ha tse ling li ile tsa hlōleha kapele. Sena se paka hore qeto ea hau ea thepa e ama ka kotloloho ho ts'epahala ha pompo.

Likarolo tsa Moralo oa Rotor

U ka finyella katleho e tsotehang le ho tšepahala ka ho tsepamisa maikutlo ho likarolo tsa moralo oa sete ea rotor ea pompo. Boenjiniere ba morao-rao bo u tlisetsa mekhoa ea phekolo e tsoetseng pele joalokaho roala ka sehatsetsi sa mocheso le ho beha mouoane oa lik'hemik'hale. Mekhoa ena e fokotsa likhohlano le ho apara, ho etsa hore li-rotor tsa hau li tšoarelle nako e telele 'me li sebetse hantle.

U rua molemo ho lilubricant tse entsoeng ka nepo tse nang le li-additives tse khethehileng. Tsena li boloka likarolo tse tsamaeang li arohane, likhohlano tse tlase, 'me li lelefatsa bophelo ba sete ea rotor ea pompo. Lisebelisoa tsa ho kopanya tse kang Finite Element Analysis (FEA) le Computational Fluid Dynamics (CFD) li u thusa ho ntlafatsa geometry ea rotor le litsela tsa ho phalla. Sena se bolela hore matla a fokolang a senyehile le mokelikeli o mongata o tsamaeang ka ho potoloha ho hong le ho hong.

- Mamello e tiileng ea tlhahiso e fokotsa ho khutla le ho lutla, ho matlafatsa ts'ebetso.

- Sistimi ea alignment ea laser e netefatsa hore shaft ea hau e potoloha hantle, e thibela khatello ea maikutlo le ho hloleha kapele.

- Meetso ea lirotha le likamore li etsa phallo e boreleli, e tsitsitseng, e loketseng maro a bobebe kapa a teteaneng.

- Li-sensor tsa nako ea 'nete le ho ithuta ka mochini li bolela esale pele litlhoko tsa tlhokomelo, ho fokotsa nako le ho boloka chelete.

Hlokomela:Ts'ebetso e tlase ea khatello ea lipompo tsa rotor e ka u pholosa ho fihlela ho 30% ea matla le ho lelefatsa bophelo ba lisebelisoa ka 20-25%.

Innovative rotor geometry e boetse e fana ka lintlafatso tse ka lekanyetsoang. Ka mohlala,ho ntlafatsa molumo oa lehare le ho tieae ntlafatsa ho nepahala ha flowmeter. Ho lokisa likarolelano tsa hub-to-tip le blade angles ho fokotsa liphoso le ho boloka ts'ebetso e tsitsitse. Ho sebelisa mekhoa ea liphatsa tsa lefutso ho ntlafatsa libopeho tsa propeller ho sehile phoso e sa tsitsang ka halofo le ho theola lebelo le lekantsoeng la phallo e tlase. Likhatelo-pele tsena tsa moralo li u thusa ho fumana molemo ka ho fetisisa ho tloha sete ea rotor ea pompo.

Ketsiso le tlhahlobo ea mohlala li tiisa melemo ena. Mohlala, moralo oa lirota tse peli o fihletse acoefficient ea matla ka holimo ho 0.44le ho ntlafatsa bokgoni ba ho fetola matla ka 9% ho feta meralo e tlwaelehileng. Liphetho tsena li bonts'a hore likhetho tse bohlale tsa moralo li lebisa katlehong ea 'nete lefatšeng.

Ho khetha Setulo sa Rotor ea Pompo e nepahetseng

U na le matla a ho fetola ts'ebetso ea sistimi ea hau ka ho khetha sete e nepahetseng ea pompo ea rotor. Qala ka ho nahana ka katleho le tšebeliso ea matla. Lisebelisoa tse sebetsang hantle haholo li ka fokotsa litšenyehelo tsa hau tsa ts'ebetso le phello ea tikoloho. Mohlala, li-rotor tsa rotor ea magnet e sa feleng lia fihlaho fihlela ho 94% e sebetsang hantle-10-12 peresente lintlha tse phahameng ho feta Motors tloaelehileng. Sena se ka u bolokela ho fihla ho 21% ts'ebelisong ea matla le ho fokotsa likhase tsa CO2 selemo le selemo ka lithane tse fetang 32 lits'ebetsong tse ling.

Ha u khetha sete ea rotor ea pompo, sheba lintlha tsena tsa bohlokoa:

- Ho sebetsa hantle le ho boloka matla

- Ho feto-fetoha ha taolo ea phallo bakeng sa litlhoko tse fetohang

- Ho tšoarella le ho apara ho hanyetsa bophelo bo bolelele

- Lerata le tlaase bakeng sa sebaka se sireletsehileng sa mosebetsi, se phutholohileng haholoanyane

- Moqapi o tiileng le ho kenya habonolo

U lokela hapesebelisa pompo ea hau ka holimo ho 60% ea Molemo oa eona oa Molemo ka ho Fetisisa (BEP)ho qoba ho thothomela le ho hloka botsitso. Boloka kheloha ea rotor e le tlase ho sireletsa litiiso le ho thibela tšenyo. Pompo e matla le mehaho ea baseplate e fokotsa ho se lumellane le khatello ea kelello. Shebella litlamorao tse kang resonance, haholo ka lipompo tsa lebelo tse fapaneng. Kamehla hlahloba ho apara, kaha ho eketseha ha tumello ho ka fokotsa katleho. Mekhoa e metle ea ho kenya - metheo e tiileng, ho tsamaisana hantle, le matla a fokolang a liphaephe - thusa pompo ea hau ea rotor hore e sebetse hantle.

Tšusumetso:Khetho e 'ngoe le e' ngoe e bohlale eo u e etsang ha u khetha le ho boloka pompo ea rotor ea hau e u atametsa haufi le ts'ebetso e phahameng le katleho e tšoarellang.

Lithuto-pale li paka boleng ba letsete la hau. Merafong, ho fetohela ho lisebelisoa tsa rotor tse sebetsang hantle haholo ho bolokile matla a ka bang 42,000 kWh selemo se seng le se seng 'me ho itefella ka nako e ka tlase ho lilemo tse peli. Litsamaisong tsa 'masepala, lintlafatso tsena li lekana le poloko ea matla ea ho nkela li-bulbs tsa incandescent tse fetang 300 ka li-LED. U ka finyella liphello tse tšoanang ka ho lebisa tlhokomelo ho pompo ea rotor e nepahetseng bakeng sa litlhoko tsa hau.

U khanna katleho ea pompo ka ho khetha rotor e nepahetseng le ho e boloka e le boemong bo holimo.

- Ho hlahlojoa khafetsa ka lintlha tse bohlale ho u thusa ho bona mathata esale pele le ho qoba ho senyeha ho bitsang chelete e ngata.

- Hlokomelakhetho ea rotore matlafatsa ts'ebetso le ho boloka chelete ka nako.

- Melemo e nyane ka katlehoe ka lebisa ho boloka chelete e ngata le ho fokotsa nako.

LBH

Ho etsahala'ng haeba u hlokomoloha tlhokomelo ea rotor?

U ipeha kotsing ea ho hloleha ha pompo le ho lokisoa ho theko e boima. Licheke tsa kamehla li boloka sistimi ea hau e le matla ebile e ka tšeptjoa. Lula u le mafolofolo 'me u shebelle pompo ea hau e atleha.

U tseba joang nako ea ho nkela rotor ea pompo sebaka?

U hlokomela lerata le makatsang, phallo e tlase, kapa ho lutla. Tšepa maikutlo a hau a tlhaho. Ketso e potlakileng e u thusa ho qoba mathata a maholo le ho boloka pompo ea hau e sebetsa hantle.

A na u ka ntlafatsa rotor ea hau ea pompo bakeng sa ts'ebetso e ntle?

Ruri! U ka khetha lisebelisoa tse tsoetseng pele kapa meralo e mecha. Ho ntlafala ho eketsa ts'ebetso e ntle mme ho lelefatsa bophelo ba pompo ea hau. Ntlafatso e 'ngoe le e' ngoe e u atametsa haufi le katleho.

Nako ea poso: Jul-09-2025