Moralo le mosebetsi oa litiiso tsa mechini li rarahane, li na le likarolo tse 'maloa tsa mantlha. Li entsoe ka lifahleho tsa litiiso, li-elastomer, litiiso tsa bobeli, le lisebelisoa, e 'ngoe le e 'ngoe e na le litšobotsi le merero e ikhethang.

Likarolo tse ka sehloohong tsa tiiso ea mechini li kenyelletsa:

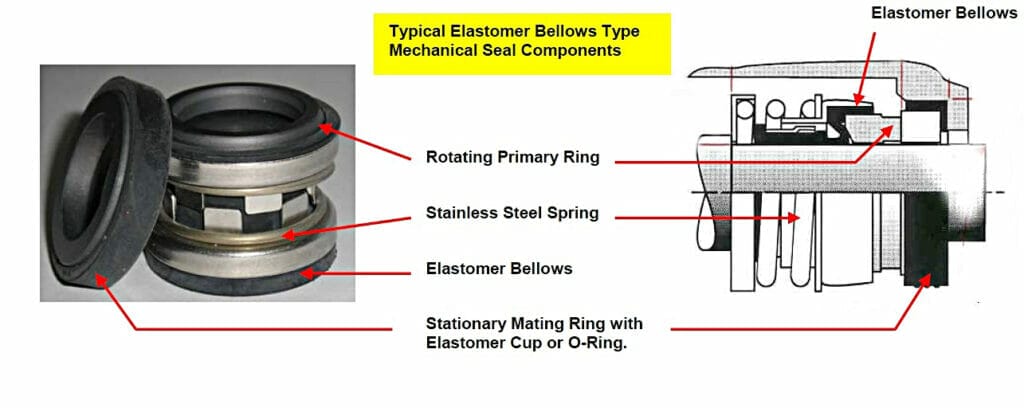

- Sefahleho se Potolohang (Lesale la Motheo):Ena ke karolo ea tiiso ea mechini e potolohang le shaft. Hangata e na le sefahleho se thata, se sa tsofaleng se entsoeng ka thepa e kang carbon, ceramic, kapa tungsten carbide.

- Sefahleho se sa sisinyeheng (Setulo kapa Lesale la Bobeli):Sefahleho se sa sisinyeheng se dula se tsitsitse mme ha se potolohane. Hangata se etswa ka thepa e bonolo e tlatsanang le sefahleho se potolohang, e leng se etsang hore ho be le sebopeho sa tiiso. Disebediswa tse tlwaelehileng di kenyeletsa ceramic, silicon carbide, le di-elastomer tse fapaneng.

- Li-elastomer:Likarolo tsa elastomeric, tse kang masale a O le li-gasket, li sebelisoa ho fana ka tiiso e tenyetsehang le e sireletsehileng pakeng tsa ntlo e sa sisinyeheng le shaft e potolohang.

- Likarolo tsa ho Tiisa tsa Bobeli:Tsena di kenyeletsa masale a bobedi a O, masale a V, kapa dikarolo tse ding tsa ho kwala tse thusang ho thibela ditshila tse kantle ho kena sebakeng sa ho kwala.

- Likarolo tsa Tšepe:Likarolo tse fapaneng tsa tšepe, tse kang sekoahelo sa tšepe kapa lebanta la ho khanna, li tšoara tiiso ea mechini hammoho ebe li e tiisa lisebelisoa.

Sefahleho sa tiiso ea mechini

- Sefahleho sa tiiso se potolohang: Lesale la mantlha, kapa sefahleho sa tiiso se potolohang, se tsamaya mmoho le karolo ya mochini o potolohang, hangata shaft. Lesale lena hangata le etswa ka thepa e thata, e tshwarellang jwalo ka silicon carbide kapa tungsten carbide. Moralo wa lesale la mantlha o netefatsa hore le ka kgona ho boloka matla a tshebetso le kgohlano e hlahiswang nakong ya tshebetso ya mochini ntle le ho fetoha kapa ho tsofala ho feteletseng.

- Sefahleho sa tiiso se sa sisinyeheng: Ho fapana le lesale la mantlha, lesale la ho kopanya le lula le sa sisinyehe. Le etselitsoe ho etsa para ea ho tiisa le lesale la mantlha. Leha le sa sisinyehe, le entsoe ho amohela motsamao oa lesale la mantlha ha le ntse le boloka tiiso e matla. Lesale la ho kopanya le atisa ho etsoa ka thepa e kang carbon, ceramic, kapa silicon carbide.

Li-elastomer (masale a O kapa mehele)

Dikarolo tsena, hangata ke masale a O kapa di-bellow, di sebeletsa ho fana ka ho tenyetseha ho hlokahalang ho boloka sekwahelo pakeng tsa kopano ya sekwahelo sa mechini le shaft kapa ntlo ya mochini. Di amohela ho se tsamaisane hantle ha shaft le ho thothomela ntle le ho beha botšepehi ba sekwahelo kotsing. Kgetho ya thepa ya elastomer e itshetlehile ka mabaka a fapaneng, ho kenyeletswa mocheso, kgatello le mofuta wa mokelikeli o kwalwang.

Litiiso tsa Bobeli

Litiiso tsa bobeli ke likarolo tse fanang ka sebaka sa ho tiisa se sa fetoheng ka har'a kopano ea tiiso ea mechini. Li ntlafatsa ts'ebetso le ts'epo ea tiiso, haholo-holo maemong a feto-fetohang.

Lisebelisoa

- Li-Springs: Li-spring li fana ka mojaro o hlokahalang lifahlehong tsa sekwahelo, li netefatsa hore li kopana khafetsa esita le tlas'a maemo a fapaneng a ts'ebetso. Ho kopana hona ho sa khaotseng ho netefatsa hore ho na le sekwahelo se tšepahalang le se sebetsang nakong eohle ea ts'ebetso ea mochini.

- Li-retainer: Li-retainer li tšoara likarolo tse fapaneng tsa tiiso hammoho. Li boloka ho lekalekana le sebaka se nepahetseng sa kopano ea tiiso, ho netefatsa ts'ebetso e ntle ka ho fetisisa.

- Lipoleiti tsa tšoelesa: Lipoleiti tsa tšoelesa li sebelisoa ho kenya tiiso mochineng. Li tšehetsa kopano ea tiiso, li e boloka e sireletsehile sebakeng sa eona.

- Seta dikurufu: Dikurufu tse sete ke dikarolo tse nyane, tse nang le dikgwele tse sebediswang ho tiisa kopano ya tiiso ya mechini ho shaft. Di netefatsa hore tiiso e boloka boemo ba yona nakong ya tshebetso, e thibela ho falla ho ka bang teng ho ka sitisang katleho ya tiiso.

Ha re phethela

Karolo e 'ngoe le e 'ngoe ea tiiso ea mechini e bapala karolo ea bohlokoa ho koaloeng ha mechine ea indasteri ka katleho. Ka ho utloisisa mosebetsi le bohlokoa ba likarolo tsena, motho a ka utloisisa ho rarahana le ho nepahala ho hlokahalang ho raleng le ho boloka litiiso tsa mechini tse sebetsang hantle.

Nako ea poso: Tshitwe-22-2023