Litiiso tsa mechini li bapala karolo ea bohlokoa lits'ebetsong tse fapaneng tsa indasteri. Li thibela ho lutla ha metsi le khase lisebelisoa tse potolohang joalo ka lipompo le li-compressor, ho netefatsa katleho ea ts'ebetso le polokeho. 'Maraka oa lefats'e oa litiiso tsa mechini o lebelletsoe ho fihla ho hoo e ka bang lidolara tse limilione tse likete tse 4.38 ka 2024, ka sekhahla sa kholo sa hoo e ka bang 6.16% selemo le selemo ho tloha ka 2024 ho isa ho 2030. Kholo ena e totobatsa bohlokoa ba tsona bo ntseng bo eketseha ho pholletsa le liindasteri. Ho na le mefuta e mengata ea litiiso tsa mechini, e 'ngoe le e 'ngoe e etselitsoe ho fihlela litlhoko le maemo a itseng a ts'ebetso, e leng se etsang hore e be ea bohlokoa haholo ho boloka ho latela tikoloho le ho ntlafatsa tlhahiso ea indasteri.

MotheoLikarolo tsa Litiiso tsa Mechanical

Litiiso tsa mechini li na le likarolo tse 'maloa tsa bohlokoa tse sebetsang hammoho ho thibela ho lutla ha lisebelisoa tsa indasteri. Ho utloisisa likarolo tsena ho thusa ho khetha setiiso se nepahetseng bakeng sa lits'ebetso tse itseng.

Lintho tsa Bohlokoa tsa ho Tiisa

Dikarolo tsa mantlha tsa ho kwala di bopa motheo wa ditiiso tsa mechini. Di ikarabella bakeng sa ho theha tshitiso e kgolo kgahlanong le ho dutla ha metsi.

Litiiso tse potolohang

Litiiso tse potolohang li hoketsoe karolong e potolohang ea lisebelisoa, joalo ka shaft ea pompo. Li tsamaea le shaft, li boloka tiiso e tiileng khahlanong le karolo e sa sisinyeheng. Motsamao ona o bohlokoa bakeng sa ho thibela ho lutla ha o ntse o lumella shaft ho potoloha ka bolokolohi.

Litiiso tse sa emeng

Litiiso tse sa sisinyeheng li lula li tsitsitse sebakeng sa tsona, hangata li khomaretsoe leboteng la lisebelisoa. Li sebetsa hammoho le litiiso tse potolohang ho theha sistimi e felletseng ea ho koala. Tiiso e sa sisinyeheng e fana ka sebaka se tsitsitseng seo tiiso e potolohang e ka hatellang holim'a sona, e leng se netefatsang tiiso e tšepahalang.

Likarolo tsa ho Tiisa tsa Bobeli

Dikarolo tsa ho kwala tsa bobedi di ntlafatsa katleho ya ditiiso tsa mechini ka ho fana ka bokgoni bo eketsehileng ba ho kwala. Di thusa ho lefella diphoso tse nyane le diphetoho maemong a tshebetso.

Mehele ea O

Masale a O ke dielemente tse chitja tsa elastomeric tse fanang ka tiiso e sa fetoheng pakeng tsa bokaholimo bo bong le bo bong. Hangata a sebediswa ditiisong tsa mechine ho thibela ditshila tsa kantle ho kena sebakeng sa tiiso. Masale a O a tenyetseha mme a ka ikamahanya le dibopeho le boholo bo fapaneng, e leng se etsang hore a lokele ditshebediso tse fapaneng.

Li-gasket

Li-gasket li sebetsa e le mofuta o mong oa karolo ea bobeli ea ho koala. Hangata li entsoe ka thepa e kang rabara kapa PTFE 'me li sebelisoa ho tlatsa sebaka se pakeng tsa libaka tse peli. Li-gasket li thusa ho thibela ho lutla ka ho etsa tiiso e tiileng, haholo-holo maemong a feto-fetohang moo ho ka bang le motsamao.

Likarolo tse ling

Ntle le likarolo tsa ho tiisa tsa mantlha le tsa bobeli, litiiso tsa mechini li kenyelletsa likarolo tse ling tse tlatsetsang ts'ebetsong ea tsona.

Li-Springs

Li-spring li bapala karolo ea bohlokoa ho bolokeng khatello lipakeng tsa litiiso tse potolohang le tse sa sisinyeheng. Li netefatsa hore litiiso li lula li hokahane, leha ho na le ho feto-fetoha ha khatello kapa mocheso. Li-spring li thusa ho amohela motsamao ofe kapa ofe oa axial, ho ntlafatsa ts'epo ea setiiso.

Likarolo tsa Tšepe

Likarolo tsa tšepe li fana ka tšehetso ea sebopeho ho litiiso tsa mechini. Li kenyelletsa likarolo tse kang matlo a tšepe le lintho tse bolokang litiiso sebakeng sa tsona. Likarolo tsena li etselitsoe ho mamella maemo a thata ao hangata a kopanang le 'ona libakeng tsa indasteri, ho netefatsa hore tiiso e tšoarella nako e telele le ho tšoarella.

Ho utloisisa likarolo tsa motheo tsa litiiso tsa mechini ho bohlokoa bakeng sa ho khetha mofuta o nepahetseng bakeng sa lits'ebetso tse ikhethileng tsa indasteri. Karolo ka 'ngoe e bapala karolo ea bohlokoa ho netefatseng katleho le ts'epo ea setiiso, qetellong e tlatsetsa katlehong e akaretsang ea lisebelisoa.

Mefuta ea Litiiso tsa Mechanical

Litiiso tsa mechine li tla ka mefuta e fapaneng, e 'ngoe le e 'ngoe e etselitsoe ho fihlela litlhoko tse itseng tsa ts'ebetso. Ho utloisisa mefuta ena ho thusa ho khetha tiiso e loketseng ka ho fetisisa bakeng sa lits'ebetso tse fapaneng tsa indasteri.

Litiiso tsa khatriche

Litiiso tsa khatriji li fana ka tharollo e kopantsoeng esale pele, e nolofatsang ho kenngoa le ho fokotsa kotsi ea liphoso. Li ntlafatsa ts'epo

Likopo le Mekhoa ea Khetho

Likopo tsa Liindasteri

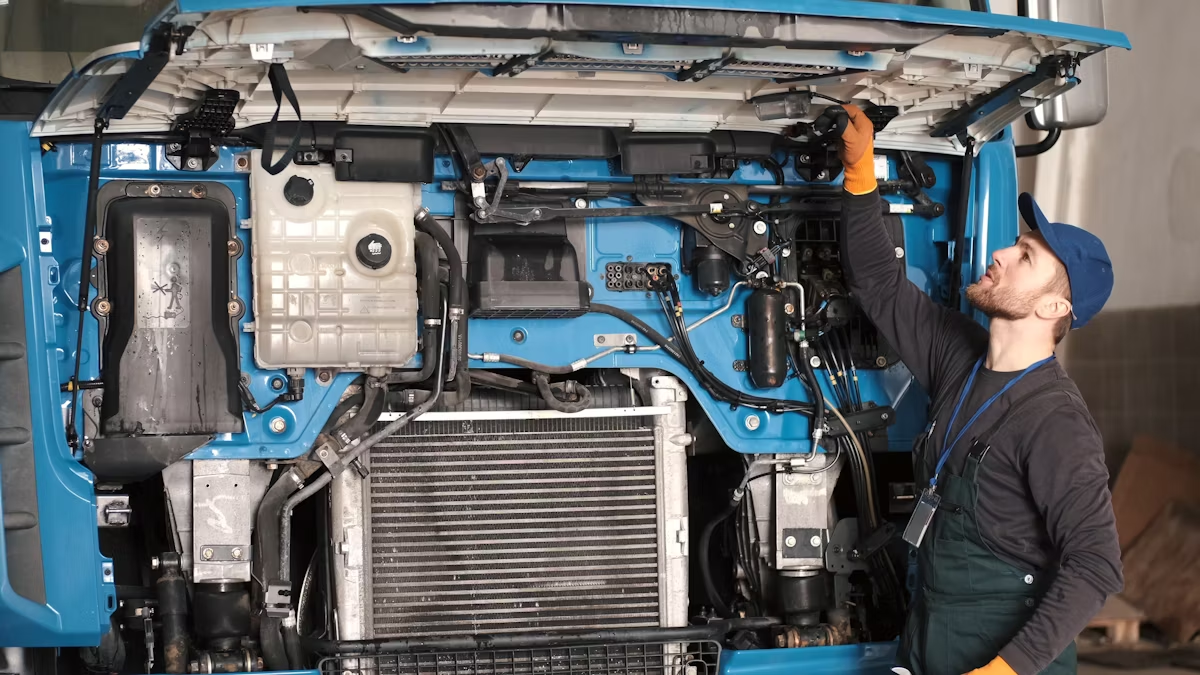

Litiiso tsa mechini li sebelisoa haholo makaleng a fapaneng a indasteri ka lebaka la bokhoni ba tsona ba ho thibela ho dutla le ho boloka botsitso ba sistimi. Liindasteri tse peli tse hlahelletseng tse itšetlehileng haholo ka litiiso tsa mechini li kenyelletsa ts'ebetso ea lik'hemik'hale le oli le khase.

Ts'ebetso ea Lik'hemik'hale

Indastering ea ts'ebetso ea lik'hemik'hale, litiiso tsa mechini li bapala karolo ea bohlokoa ho netefatseng hore metsi a kotsi a lula a sireletsehile. Li thibela ho lutla ha lipompo le li-mixer, e leng ntho ea bohlokoa bakeng sa ho boloka polokeho le ho latela melao ea tikoloho. Litiiso li thusa ho boloka botšepehi ba lisebelisoa tsa ts'ebetso ka ho thibela tšilafalo le ho netefatsa hore lik'hemik'hale li lula li le ka har'a litsamaiso tse khethiloeng. Ts'ebeliso ena e totobatsa bohlokoa ba ho khetha litiiso tse ka mamellang lik'hemik'hale tse mabifi le mocheso o fapaneng.

Oli le Khase

Indasteri ea oli le khase e hloka litharollo tse matla le tse tšepahalang tsa ho koala ka lebaka la tikoloho e nang le khatello e phahameng e kopanang le lits'ebetso tsa ho cheka le ho ntša metsi. Litiiso tsa mechini lia hlokahala ho thibela ho lutla ho ka lebisang ho hloleheng ho hoholo kapa likotsi tsa tikoloho. Tlhoko e ntseng e eketseha ea litiiso tsa mechini tse tšoarellang nako e telele le tse sebetsang hantle lefapheng lena e totobatsa karolo ea tsona ea bohlokoa ho bolokeng polokeho ea ts'ebetso le katleho. Litiiso tse sebelisoang lits'ebetsong tsa oli le khase li tlameha ho mamella khatello le mocheso o feteletseng, e leng se etsang hore khetho ea thepa le meralo e loketseng e be ea bohlokoa.

Mekhoa ea Khetho

Ho khetha tiiso e nepahetseng ea mechini ho kenyelletsa ho nahana ka lintlha tse 'maloa ho netefatsa ts'ebetso e ntle le nako e telele. Litekanyetso tsa bohlokoa li kenyelletsa maemo a mocheso le khatello, hammoho le ho lumellana ha mokelikeli.

Maemo a Mocheso le Khatello

Litiiso tsa mechini li tlameha ho mamella mocheso le khatello e itseng ea ts'ebeliso. Libaka tse nang le mocheso o phahameng li hloka litiiso tse entsoeng ka thepa e ka hanelang ho senyeha ha mocheso. Ka mokhoa o ts'oanang, litiiso tse sebelisoang lits'ebetsong tse nang le khatello e phahameng li tlameha ho etsoa ho sebetsana le meroalo ea axial ntle le ho beha kotsing ea tsona.

Nako ea poso: Mphalane-31-2024