Liphihlelo tse ngata tsa tsamaiso ea merero le mohlala o ikhethileng oa mofani oa litšebeletso li etsa hore puisano ea mokhatlo e be ea bohlokoa le kutloisiso ea rona e bonolo ea litebello tsa hau bakeng sa tiiso ea mechini ea eMG1 bakeng sa indasteri ea likepe, Joale re na le boiphihlelo ba lilemo tse fetang 20 indastering ena, 'me thekiso ea rona ea kakaretso e tšoaneleha hantle. Re ka u fa malebela a profeshenale ka ho fetisisa ho fihlela litlhoko tsa lihlahisoa tsa hau. Mathata afe kapa afe, a re hlaheleng!

Liphihlelo tse ngata tsa tsamaiso ea merero le mohlala o itseng oa mofani oa litšebeletso li etsa hore puisano ea mokhatlo e be ea bohlokoa haholo le kutloisiso ea rona e bonolo ea litebello tsa hau bakeng sa lisebelisoa tsa rona tse tsoetseng pele, tsamaiso ea boleng bo holimo, bokhoni ba lipatlisiso le nts'etsopele bo theohe. Theko eo re fanang ka eona e kanna ea se be e tlase ka ho fetisisa, empa re tiisa hore e qothisana lehlokoa ka botlalo! Rea u amohela ho ikopanya le rona hang-hang bakeng sa kamano ea khoebo ea nakong e tlang le katleho ea bobeli!

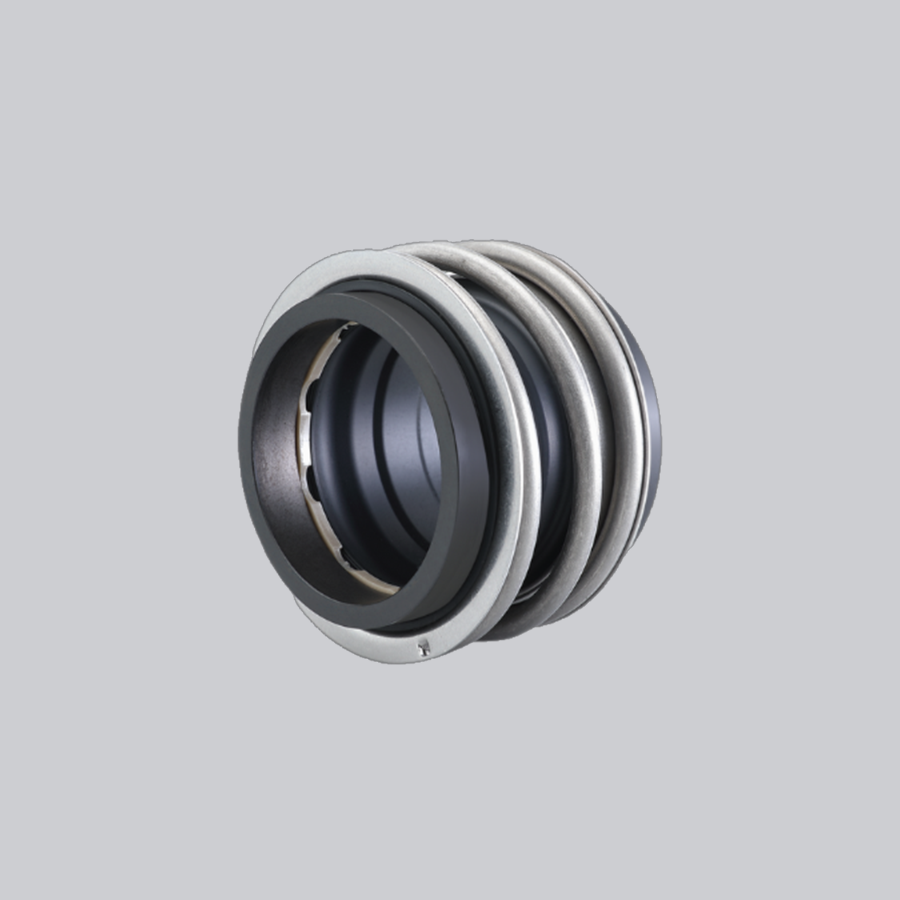

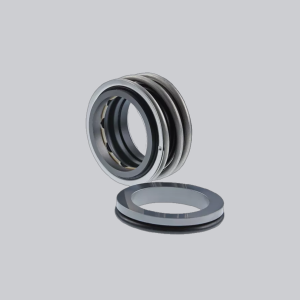

Likaroloana

Bakeng sa li-shaft tse sa rarahanang

Tiiso e le 'ngoe le e habeli

Elastomer e benya e potoloha

E leka-lekaneng

Ho sa tsotelehe hore na teko ea ho potoloha e shebane le tataiso efe

Melemo

- E lumellana ka 100% leMG1

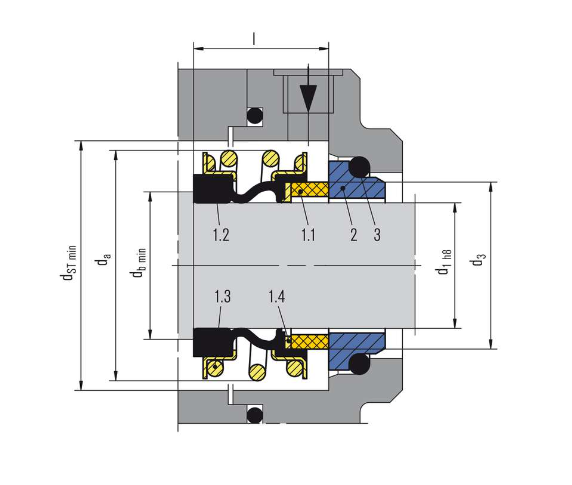

- Bophara bo bonyenyane ba kantle ba tšehetso ea bellows (dbmin) bo nolofalletsa tšehetso ea lesale le tšoarellang ka kotloloho, kapa mehele e menyenyane ea sebaka

- Tšobotsi e ntle ea ho hokahanya ka ho itlhoekisa disk/shaft

- Ho ntlafatsa ho tsepamisa maikutlo ho pholletsa le mefuta eohle ea ts'ebetso ea khatello

- Ha ho na ho torsion holim'a bellows

- Tšireletso ea shaft holim'a bolelele bohle ba tiiso

- Tšireletso ea sefahleho sa tiiso nakong ea ho kenngoa ka lebaka la moralo o khethehileng oa bellows

- Ha e na kutloelo-bohloko ho kheloha ha shaft ka lebaka la bokhoni bo boholo ba ho sisinyeha ha axial

- E loketse lits'ebetso tse se nang likokoana-hloko tse tlase

Lisebelisoa tse khothaletsoang

- Phepelo ea metsi a hloekileng

- Boenjiniere ba lits'ebeletso tsa kaho

- Theknoloji ea metsi a litšila

- Theknoloji ea lijo

- Tlhahiso ea tsoekere

- Indasteri ea makhasi le pampiri

- Indasteri ea oli

- Indasteri ea Petrochemical

- Indasteri ea lik'hemik'hale

- Metsi, metsi a litšila, marotholi a metsi

(lintho tse tiileng ho fihlela ho 5% ka boima) - Makhasi (ho fihlela ho 4% ho feta)

- Latex

- Mabese, lino tse tahang

- Marotholi a sulfide

- Lik'hemik'hale

- Oli

- Lipompo tse tloaelehileng tsa lik'hemik'hale

- Lipompo tsa sekere tsa Helical

- Lipompo tsa thepa

- Lipompo tse potolohang

- Lipompo tse ka qoelisoang ka metsing

- Lipompo tsa metsi le metsi a litšila

s

Mefuta e sebetsang

Bophara ba mokoti:

d1 = 14 … 110 mm (0.55″ … 4.33″)

Khatello: p1 = 18 bare (261 PSI),

vacuum … 0.5 bare (7.25 PSI),

ho fihlela ho 1 bar (14.5 PSI) e nang le setulo se notleloang

Mocheso: t = -20 °C … +140 °C

(-4 °F … +284 °F)

Lebelo la ho thella: vg = 10 m/s (33 ft/s)

Motsamao o amohelehang oa axial: ± 2.0 mm (± 0.08″)

Lisebelisoa tsa motsoako

Lesale le sa sisinyeheng: Ceramic, Carbon, SIC, SSIC, TC

Lesale le potolohang: Ceramic, Carbon, SIC, SSIC, TC

Tiiso ea Bobeli: NBR/EPDM/Viton

Likarolo tsa Selemo le Tšepe: SS304/SS316

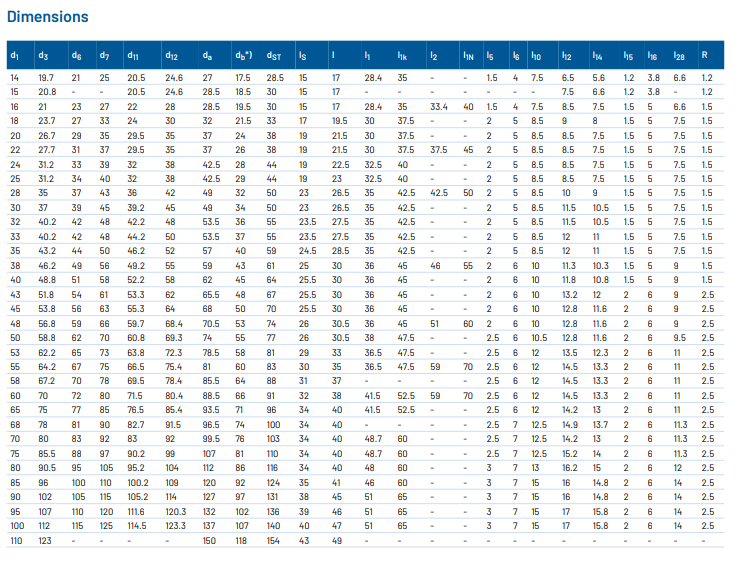

Leqephe la data la WeMG1 la tekanyo(mm)

tiiso ea pompo ea mechini bakeng sa indasteri ea likepe